This engine was known at the time as the "Hillmaster"

The obvious improvment for this engine was the addition of a third main bearing in the center of the crank to supplement the two at each end (all steel backed babbits). Crankcase capacity increased from 4 to seven pints, and it was pressure lubricated. This had the effect of improving reliability, particularly at high speeds. The stroke was also lengthed and it was slightly bored out. Compression was further increased to 7.4 . The old, and beautifully cast alloy Tilotson carburetor (M10/M10A) was rejected in favor of the Zenith, a lumpy looking iron affair that might have been cast in a barn somewhere. Both are updraft units.In general the three main "Hillmaster" is regarded as the best engine Bantam made and it developed about 22 horsepower. You can read in the Autmobile Quarterly article about Alex Tremulis' rave reviews on his cross country trip with the first "Hollywood" and believe or not depending on your level of enthusiasm. (...cruised at 75-80 and averaged 42.5 mpg.") However, with the three main, the light Roadsters were apparently capable of 0-30 times of 5.5 seconds which is fairly quick for the day, and they were still "economy cars" in that they could deliver 42 to 56 mpg. Certainly one could cruise comfortably at 45 or 50 without any trouble.

Bantam 3 main specs.

How can you tell by just looking what you have? Anyone care to offer a comment?

Well, there is the engine number...anything above #65500 is a three main IF the number hasn't been tampered with. The existence of a Zenith rather than a Tilotson would be an indicator.

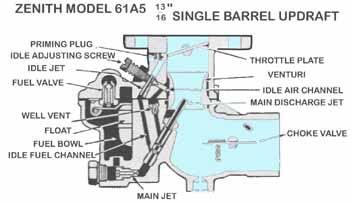

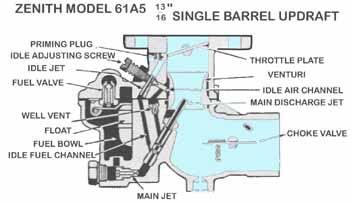

Here's a schematic of the Zenith. It was to be used with an AC # A152903 air cleaner. Oil wetted type Std. Note that this carb has no high speed adjustment, only an idle adjustment.

Don't run this thing too lean plugs and valves.

IDLE ADJUSTMENT. With engine warm and idling, set idle adjusting screw so that engine fires smoothly. Idler screw should be set approximately one and a half turns out from inner seated position and setting should be varied only slightly. Set throttle stopscrew for idle speed of 7mph.

FLOAT LEVEL. Bottom of float at free end should be 1 5/32" from gasket seat of throttle body with needle valve closed (invert throttle body to check)

FILTER: Empty regularly.