When the new Bantam company emerged from the American Austin Companies ashes it was necessary to develop a stonger engine...and a different one so as to avoid the Austin licensing royalty. Thus, the noisy Austin roller/ball main bearings were eliminated in favor of the more usual (and less expensive) babbited bearings. Compression was raised to 7.0 to 1 (from the Austin's 5 to 1) which initself gave nearly 50% more power, boosting it up to a heady 19 hp (from 13).

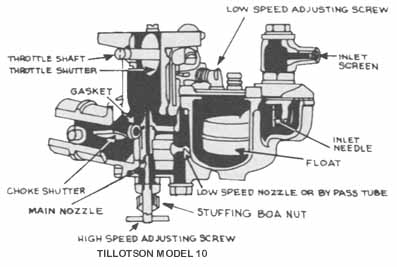

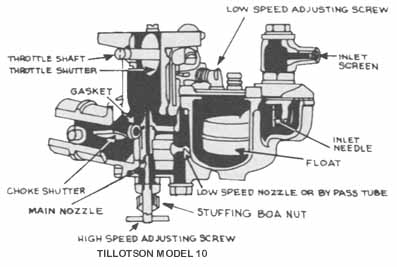

TILLOTSON CARBURETOR MODEL M10 3/4" updraft single bbl.

SET UP

The Tillotson has two adjustments...idling and high speed. All adjustments must be made in the following order:

TROUBLE SHOOTING

This is a simple tube type updraft unit. Given that your unit has been rebuilt or is new, there are three things to look for if you are having trouble getting maximum performance and economy (according to service letter B-24).

1. Dirt or water in the carburetor. The smallest particle of dirt will obstruct and prevent proper metering. Look for dirt in the by pass tube if the engine won't idle well, stalls easily, or has irregular or spotty operation. If the engine will not accelerated readilly when warm, back-fires or refuses to perform at high spped, look for dirt in the main nozzle. Water can get in the gas by condensation, so, keep the tank as full as possible. You will have to drain the traps and clean the screen every 30 days.

If you are taking one of tings apart to clean, be careful unscrewing the nozzles or you can destroy the internal threads. USE AIR to clean out metering holes NEVER USE WIRE etc. to pick at them

2. Air leaks in the inlet manifold or manifold gaskets

3. maintainence of proper fuel level.